Category Archives: Ingredients

When It Comes to Spark Plug Wires, All Are Not Created Equal

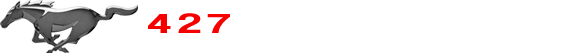

It came time to to find some spark plug wires for my retro mod SN95 Ford Racing X Head 427. The 427 was based off the Boss 351W block, so I needed wires that were compatible with the 5.8 liter engine.

Prior experience showed that the “pre-cut” wires led to misery. There was always enough wire; there was always too much wire. So my great looking engine was covered with spark plug wire spaghetti…no one made enough wire retainers to avoid the inevitable.

The final selection was the MSD Ignition 8.5 mm Super Conductor Wires (31323) . The wires are a “universal” set, which means that you must cut-to-fit. The spark plug side boots are gray silicon rubber. More importantly, the spark plug ends are bendable, which keeps the silicon rubber away from the headers.

The distributor ends are the “cut-to-fit” portion of the deal.

Assembling the Plug Wires

You must buy two items to handle the cut-to-fit spark plug wires:

- An Accel Wire Crimping Tool (170036) – It will be the best investment that you ever made. Thank me later. This tool is a bit incredible in that it has crimp dies for both MSD spark plug crimps.

- MSD Spark Guard Dielectric Grease – The distributor-side boot will slide on very nicely once the grease is applied. If you do not use the grease, you will spend a frustrating afternoon fighting the wires.

MSD Ignition 8.5 mm Super Conductor Wires (31323) have great instructions for the cutting and crimping sequence. The Accel crimper will do a great job of attaching the distributor-side crimp terminals. The quality of the MSD wires are beyond reproach. MSD advertises 40 to 50 Ohms resistance per foot…they deliver.

I performed a comparison of the resistance between another set of cut-to-fit spark plug wires: Ford Racing Wire Set M-12259-M302. The Ford Racing wires have a simple crimp compared to the MSD wires. It was so simple, I really questioned whether the crimp would be effective. It was not. I compared the resistance of the MSD wires to the Ford Racing wires. The results are shown below:

| Plug |

MSD Plug Wires (Ohms) |

Ford Racing Wires (Ohms) |

| 1 |

80.8 |

2010 |

| 2 |

90.1 |

2059 |

| 3 |

90.0 |

860,000 |

| 4 |

109.2 |

1,230,000 |

| 5 |

82.8 |

1,500,000 |

| 6 |

84.8 |

1,030,000 |

| 7 |

90.8 |

2050 |

| 8 |

83.7 |

2109 |

As you can see, the ford Racing wire resistances were all over the place. The MSD results were dead consistent and in line with their 40 to 50 Ohms per foot claim. Case closed.

Ford Racing Crate Engine Changes to Fit 1994 SN95 Mustang

Changes to the Ford Racing M-6007-X427FRT 427 to Fit a 1994/95 SN95 Mustang

Does a Ford Racing X-Head 427 (M-6007-X427FRT) want to fit into the 1994/95 Mustang SN95 chassis? Hell yes. Does it fit when received from Ford Racing…not hardly. Let’s go through key changes for a Mustang engine swap.

Start with basics. The standard Mustang GT engine was the venerable 302 pushrod V8. You have choices…stroke the 302 up to 347 cubic inches?…stroke up to 363? The next step would be to drop a 351-based engine into the Mustang.

But, Ford had already done this experiment. Versions of the 1995 Mustang Cobra R model had a Ford 351 W dropped in place of the 302. The Cobra R 351 produced only 300 HP, and only 250 units were produced. By, 1996, the 302 and 351 pushrod engines were extinct…end of era. Period.

The Ford Racing X-Head 427 comes in two variants: the front pan FFT and the rear pan FRT. The 351 engine was intended for front sump service, but the SN95 Mustang demands rear sump. It turns out to be a bit academic because neither Ford Racing pan fits the SN95 Mustang.

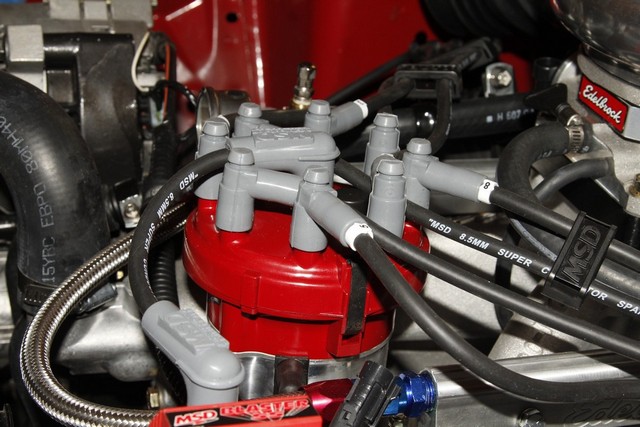

What else on the Ford Racing crate engine does not fit the SN95? Here goes:

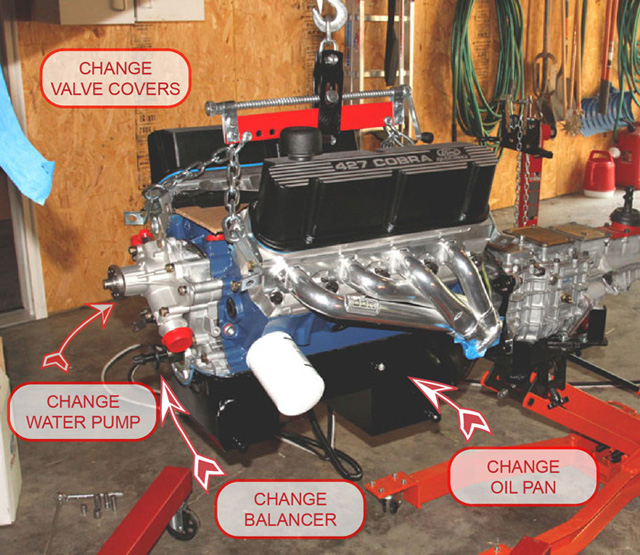

- The oil pan, and consequently, the oil pickup tube that will have to be replaced during the oil pan swap out. Yes, you will find that your engine rests on top of the steering gear (Figure 1, below)…you can either keep it in this condition and eliminate the motor mounts OR you can buy the 5 quart (instead of 7 quart) 351W oil pan from Summit Racing (M-6675-A58), and it will fit quite well. It will give you about 3/8 inch clearance to the steering gear and 3/8 inch clearance to the factory add-on stiffener bars beneath the engine.

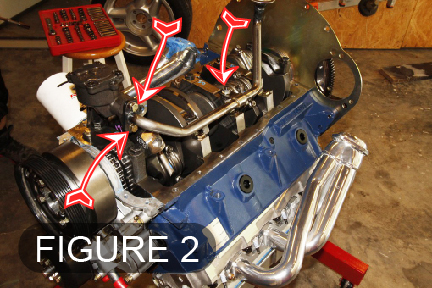

Remember to change the engine oil more frequently. You do not have to be a brain scientist to change out the oil pickup tube…the tube does come with the oil pan. As shown in Figure 2 (below), invert the engine while on the stand; remove the two bolts at the pump, then the one nut on the tube mid-span. The oil pickup that is sent with the M-6675-A58 oil pan fits decently well.

- The valve covers. The Ford Racing crate engine is equipped with the cool-looking cast aluminum black valve covers (M-4582-W427B) shown in the photo above. Put them on eBay. You will eventually find that the Edelbrock Pro-Flo 2 intake manifold and throttle body gives you virtually no room to maneuver a 4 inch diameter intake tube to the passenger’s side firewall…they simply are too tall. You will also eventually find that the back of your alternator slams into the valve because you will be able to re-use your huge right and left cast aluminum accessory mounts…this makes life a whole lot easier. I bought the cool looking Ford Racing M-6582-A302R polished cast aluminum valve covers. The provide plenty of air intake tube clearance as well as room for the alternator. I had the opportunity to use the new-style Fel-Pro PermaDryPlus valve cover gaskets QVS13264T from Summit…a far improvement from the cork gasket/black ooze days. One must remember, however, that the PermaDryPlus gaskets have little tolerance for over-torquing. I found out the hard way that 60 inch-pounds (i.e., 5 ft-lbs) is plenty of torque to seal these gaskets.

- The water pump and timing chain cover. It seems kinda sad to have to rip the whole front off a new Ford Racing crate engine, but this is required. The SN95 Mustangs used an electric fan in place of the conventional belt driven fan. Consequently, the SN95 water pump is a short snout “reverse rotation” water pump. Any of the aftermarket 302/351 water pump and timing chain covers will work well. Perform the timing chain cover change out while you are doing the oil pan change out as the gaskets are much, much easier to handle. You can thank me later. While performing the timing chain cover change out, you will have to remove the mechanical fuel pump eccentric from the end of the cam shaft…this is what make the “short snout” water pump short. If you don’t remove the eccentric, the new timing chain cover will not install. I used the “new style” dry Fel-Pro QOS30214T pan gasket from Summit…great fit…I remember the days of cork gaskets and dope, so this was a treat to deal with. As I am showing my age, I used the Permatex High Tack Spray-A-Gasket sealant on the water pump gaskets. This was some incredibly good stuff to use. I remember the days of black ooze and brushes.

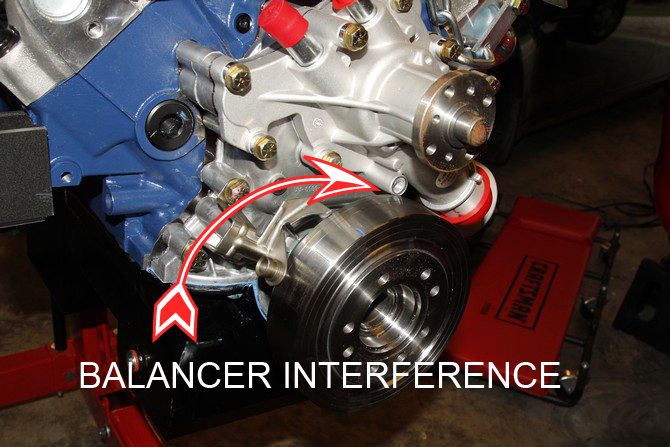

- The harmonic balancer. The Ford racing crate engine comes with an absolutely beautiful polished harmonic balancer. The purpose of the harmonic balancer is to absorb the torsional vibration energy as each cylinder fires. When you pull the harmonic balancer to change the timing chain cover, remove the pretty Ford Racing balancer and put it on Craig’s List…you will have to replace it because it is too large in diameter for the new reverse rotation water pump that you just installed. The scene looks like Figure 3:

The diameter of the Ford Racing 7 inch balancer is too large and strikes a water pump boss. It became a true adventure to replace the harmonic balancer for this engine. Ford had a long history of using multiple Top Dead Center (TDC) markings for their engines with different pointer locations. Keep in mind, when the crankshaft keyway is in the 12 o’clock position and the front right (No. 1) cylinder is at TDC on the compression stroke, you have found true TDC, at least for timing purposes. I tried one balancer that had at least 4 different TDC positions on it. Another had TDC situated 30 degrees away from my TDC pointer. I finally settled on a harmonic balancer from Advance Auto that was made for the 302 engine, and had the proper extension to align the crankshaft pulley to the proper position for the serpentine belt. The balancer had a 28 oz weight affixed to it…this MUST BE REMOVED because the Ford Racing crate engines are ZERO BALANCE engines. In other words, they are balanced internal to the engine, and you cannot use an external weight on either the flywheel nor the harmonic balancer…bad vibration things will happen very quickly at your first firing. The offset weights simply attached to the balancer using two allen screws.

Ford 351 Engine Swap Ingredients

A Little History

Fortunately, I was able to purchase a low mileage 1994 SN95 Mustang. There was a whopping 2,400 miles on the vehicle when delivered to me via motor carrier. As this unit had a white convertible top, I insisted on TOP CARRY ONLY. There was no use to having well-used motor oil dripping from a 1984 Impala stationed above the Mustang.

The 1994 Mustang was a bit of an oddball. It was the first in the 10 year run from 1994-2004. Technically, the chassis was a modified Fox monocoque unibody (no underbody frame). The Mustang Purists shun the 1994 because of the horizontal slat tail lamps (Figure 1)

The 1994 Mustang GT was equipped with an anemic 302 pushrod V-8 engine. Power was downgraded to 215 HP, which was well within the capability of the Borg Warner T-5 5 speed manual transmission. The 1994-1995 SN95 Mustangs were the last time that Ford used the T-5 behind a V-8 engine. The SN95 bellhousings were made 5/8 inch longer than Fox versions to place the shifter in correct location relative to the body. The 5/8 inch difference must be compensated with a driveshaft spacer when a Tremec TKO transmission is swapped along with the engine.

The 1994 and 1995 SN95 Mustangs share almost complete commonality, at least in the major components. The 1996 SN95 Mustang was equipped with a Tremec T-45 manual transmission as well as the Ford Modular 4.6 L overhead cam engine. This was pretty much the end of the Hot Rod Era. The 1999-2004 Mustangs, all equipped with the Modular engine, had further refinements and were commonly known a “New Edge” Mustangs.

When buying parts for a 1994/1995 SN95 engine and transmission swap, many vendors will advertise that parts are common during the 1994 through 1998 years. That may be true for some parts, but stick to the parts specifically listed for 1994/95. For example, the Magnaflow Catback Exhaust system is commonly listed for 1994-1998 SN95 Mustangs. It may be great for 1996 through 1998 Mustangs, but the passenger side pipes definitely do not fit a 1994.

Necessary Ingredients:

-

Swap engine – I selected the Ford Racing M-6007-X427RFT crate engine (Figure 2).

Figure 2 – Ford X-Head 427 M-6007-X427RFT Engine

The jury is still out whether this was a proper engine selection. I had an internal problem with the engine, which necessitated the engine to be shipped back to Ford Racing in Livonia, MI. It has been 3 1/2 weeks, and I still have no diagnosis, correction plan or return date.

The Ford Racing X-Head 427 M-6007-X427RFT is based on the Boss 351 block. The engine is rated at 450 HP and a whopping 520 ft-lbs of torque.

The advantages of the 351-based engine are enormous:

- The bellhousing patterns are common with the 302

- The engine mounts are common with the 302

- For the most part, the accessory drive bolting is common with the 302

It should be noted that the main difference between the 302 and 351 is the deck height. Deck height is the distance between the center of the crankshaft and the machined head interface. The 302 has a 8.2 inch deck height, whereas the 351 has a 9.5 inch deck height. More deck height = more torque, period.

Consequently, the 302 and 351-based engines do not share intake manifolds or exhaust headers. This is one reason that God created the so called “swap headers”. The 351 swap headers are designed to “correct” the raised deck height of the 351 swap engine so that a catback exhaust system designed for the 302-based SN95 Mustang will properly fit. As I will discuss at length in another post, not all swap headers are created equal.

2. The transmission – I selected the Tremec TKO-600 5 speed transmission (Figure 3):

The Borg-Warner T-5 5 speed that was OEM was rated at 300 ft-lbs. Needless to say, the Ford Racing X-Head 427 torque rating of 520 ft-lbs was going to cause a problem.

I purchased the Quicktime RM-6065 bellhousing from Summit Racing (QTI-RM-6065) – Figure 4.

As shown in Figure 4, the unit came with the block plate and was specifically designed to mate with the Tremec TKO transmissions. There were two adapter rings (one specifically for Tremec) that slipped into the transmission-side hole.

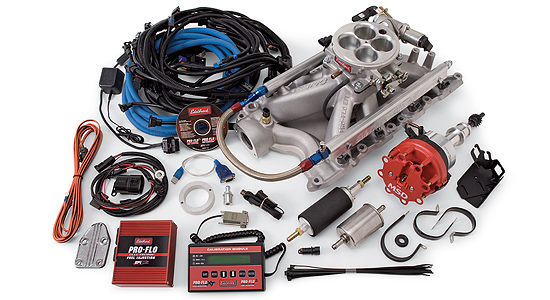

3. Fuel injection – I selected the Edelbrock 35410 Pro-Flo 2 System to provide air, fuel and spark (Figure 5)

Figure 5 – Edelbrock 35410 Pro-Flo 2 Fuel Injection

As shown in Figure 5, the Edelbrock system is a complete system, ready to control not only the fuel/air mixture, but spark timing. Some competing systems only control fuel/air. A special narrow-neck distributor is included to ensure no interference with the water channels cored into the front of the intake manifold.

The distributor controls spark (via the computer) using a Hall Effect sensor within the housing. A high capacity and pressure (Walbro) fuel pump, hoses, fittings, clips and wiring harnesses are included.

The control system is based on Speed-Density logic; in other words, one of your first steps is to remove and discard the HUGE OEM air filter housing, which includes the MAF (mass air flow) sensor that is needed to drive the Ford Electronic Engine Control (EEC). As a matter of fact, you will be cutting out damn near ever wire leading into the engine compartment if you use the Pro-Flo 2 system…it literally stands alone and takes control. You will even be tossing the entire EEC computer that is situated behind the passenger’s side kick panel. Even better, you will never again pick up a CHECK ENGINE light, because the EEC computer provides power to the light!

A disadvantage of the Edelbrock Pro-Flo 2 selection is that it is not a “learning system”…it is a “somewhat learning system”. The FAST EFI control system, which does not control spark, does do a decent job at real time mixture trimming by monitoring exhaust oxygen (via the oxygen sensor). The Edelbrock Pro-Flo 2 system will provide a small range of mixture trimming (+/- 15%) if operated in closed loop control.

But, I’ll say it up front, if you want to tune your engine, if you want to know exactlywhat your AIR/FUEL ratio is, you will be laying out an extra $400 for the Edelbrock 3532 Dual Channel Air/Fuel Ratio Monitor. The kit comes with one wide band oxygen sensor that will go in place of the Pro-Flo 2 narrow band sensor. Simply put, a narrow band sensor only tells you whether you are lean, just right or too rich, but not by how much. The wide band sensor tells you EXACTLY what your AIR/FUEL ratio is, from 10.0 to 20.0. You will thank me later.

New Ford Racing X-Head 427 (M-6007-X427FRT)

Welcome to 427 Mustang!

This site is dedicated the steps, challenges and victories in retrofitting a Ford Racing X-Head 427 engine into a 1994 SN95 Mustang GT.

In short:

- YES, the Ford Racing M-6007-X427FRT 450 HP/520 ft-lb engine does fit into a SN95 Mustang

- YES, both the engine and the Mustang require modifications…you will not have to use a cutting torch/welder to get the engine to fit

- Yes, if you modify one thing, you’ll find that you have to modify two other things that you never thought about

- YES, you will send Summit Racing and Jeg’s a lot of money…they will become your best friends

- YES, there are many ways to tackle this project…some ways require more money than others

- YES, part vendors advertise that their parts will fit the SN95…sometimes they don’t

- YES, some vendors will send you defective products…you will learn to check parts before installing them

- Yes, eventually this site will answer: How can I do a 351W engine swap in a SN95 Mustang GT in less than 1,721 steps

I hope to to give give all builders the benefit of my experience … hopefully you will save some $$$ and a whole lot of whiskey.