Tag Archives: air/fuel

Ford 351 Engine Swap Ingredients

A Little History

Fortunately, I was able to purchase a low mileage 1994 SN95 Mustang. There was a whopping 2,400 miles on the vehicle when delivered to me via motor carrier. As this unit had a white convertible top, I insisted on TOP CARRY ONLY. There was no use to having well-used motor oil dripping from a 1984 Impala stationed above the Mustang.

The 1994 Mustang was a bit of an oddball. It was the first in the 10 year run from 1994-2004. Technically, the chassis was a modified Fox monocoque unibody (no underbody frame). The Mustang Purists shun the 1994 because of the horizontal slat tail lamps (Figure 1)

The 1994 Mustang GT was equipped with an anemic 302 pushrod V-8 engine. Power was downgraded to 215 HP, which was well within the capability of the Borg Warner T-5 5 speed manual transmission. The 1994-1995 SN95 Mustangs were the last time that Ford used the T-5 behind a V-8 engine. The SN95 bellhousings were made 5/8 inch longer than Fox versions to place the shifter in correct location relative to the body. The 5/8 inch difference must be compensated with a driveshaft spacer when a Tremec TKO transmission is swapped along with the engine.

The 1994 and 1995 SN95 Mustangs share almost complete commonality, at least in the major components. The 1996 SN95 Mustang was equipped with a Tremec T-45 manual transmission as well as the Ford Modular 4.6 L overhead cam engine. This was pretty much the end of the Hot Rod Era. The 1999-2004 Mustangs, all equipped with the Modular engine, had further refinements and were commonly known a “New Edge” Mustangs.

When buying parts for a 1994/1995 SN95 engine and transmission swap, many vendors will advertise that parts are common during the 1994 through 1998 years. That may be true for some parts, but stick to the parts specifically listed for 1994/95. For example, the Magnaflow Catback Exhaust system is commonly listed for 1994-1998 SN95 Mustangs. It may be great for 1996 through 1998 Mustangs, but the passenger side pipes definitely do not fit a 1994.

Necessary Ingredients:

-

Swap engine – I selected the Ford Racing M-6007-X427RFT crate engine (Figure 2).

Figure 2 – Ford X-Head 427 M-6007-X427RFT Engine

The jury is still out whether this was a proper engine selection. I had an internal problem with the engine, which necessitated the engine to be shipped back to Ford Racing in Livonia, MI. It has been 3 1/2 weeks, and I still have no diagnosis, correction plan or return date.

The Ford Racing X-Head 427 M-6007-X427RFT is based on the Boss 351 block. The engine is rated at 450 HP and a whopping 520 ft-lbs of torque.

The advantages of the 351-based engine are enormous:

- The bellhousing patterns are common with the 302

- The engine mounts are common with the 302

- For the most part, the accessory drive bolting is common with the 302

It should be noted that the main difference between the 302 and 351 is the deck height. Deck height is the distance between the center of the crankshaft and the machined head interface. The 302 has a 8.2 inch deck height, whereas the 351 has a 9.5 inch deck height. More deck height = more torque, period.

Consequently, the 302 and 351-based engines do not share intake manifolds or exhaust headers. This is one reason that God created the so called “swap headers”. The 351 swap headers are designed to “correct” the raised deck height of the 351 swap engine so that a catback exhaust system designed for the 302-based SN95 Mustang will properly fit. As I will discuss at length in another post, not all swap headers are created equal.

2. The transmission – I selected the Tremec TKO-600 5 speed transmission (Figure 3):

The Borg-Warner T-5 5 speed that was OEM was rated at 300 ft-lbs. Needless to say, the Ford Racing X-Head 427 torque rating of 520 ft-lbs was going to cause a problem.

I purchased the Quicktime RM-6065 bellhousing from Summit Racing (QTI-RM-6065) – Figure 4.

As shown in Figure 4, the unit came with the block plate and was specifically designed to mate with the Tremec TKO transmissions. There were two adapter rings (one specifically for Tremec) that slipped into the transmission-side hole.

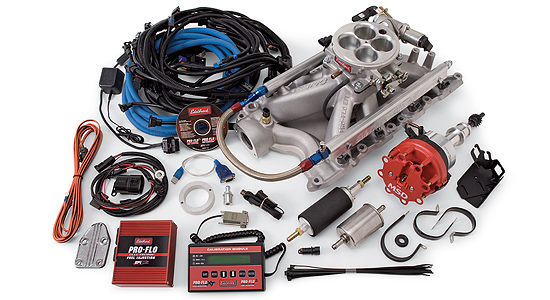

3. Fuel injection – I selected the Edelbrock 35410 Pro-Flo 2 System to provide air, fuel and spark (Figure 5)

Figure 5 – Edelbrock 35410 Pro-Flo 2 Fuel Injection

As shown in Figure 5, the Edelbrock system is a complete system, ready to control not only the fuel/air mixture, but spark timing. Some competing systems only control fuel/air. A special narrow-neck distributor is included to ensure no interference with the water channels cored into the front of the intake manifold.

The distributor controls spark (via the computer) using a Hall Effect sensor within the housing. A high capacity and pressure (Walbro) fuel pump, hoses, fittings, clips and wiring harnesses are included.

The control system is based on Speed-Density logic; in other words, one of your first steps is to remove and discard the HUGE OEM air filter housing, which includes the MAF (mass air flow) sensor that is needed to drive the Ford Electronic Engine Control (EEC). As a matter of fact, you will be cutting out damn near ever wire leading into the engine compartment if you use the Pro-Flo 2 system…it literally stands alone and takes control. You will even be tossing the entire EEC computer that is situated behind the passenger’s side kick panel. Even better, you will never again pick up a CHECK ENGINE light, because the EEC computer provides power to the light!

A disadvantage of the Edelbrock Pro-Flo 2 selection is that it is not a “learning system”…it is a “somewhat learning system”. The FAST EFI control system, which does not control spark, does do a decent job at real time mixture trimming by monitoring exhaust oxygen (via the oxygen sensor). The Edelbrock Pro-Flo 2 system will provide a small range of mixture trimming (+/- 15%) if operated in closed loop control.

But, I’ll say it up front, if you want to tune your engine, if you want to know exactlywhat your AIR/FUEL ratio is, you will be laying out an extra $400 for the Edelbrock 3532 Dual Channel Air/Fuel Ratio Monitor. The kit comes with one wide band oxygen sensor that will go in place of the Pro-Flo 2 narrow band sensor. Simply put, a narrow band sensor only tells you whether you are lean, just right or too rich, but not by how much. The wide band sensor tells you EXACTLY what your AIR/FUEL ratio is, from 10.0 to 20.0. You will thank me later.